So, you’ve got your brand new disc. Or old disc. Whatever. You want to give it some pizzaz or that something extra that makes it yours. Or, maybe you like tattoos and want your disc to have one too. This walk-through can help you achieve any and all of those things!

Tonight, I am going to apply a custom stencil design to a new Innova Star Valkyrie. To do this, I am going to need a few things:

- A design to stencil

- Adhesive vinyl

- X-acto knife

- iDye Poly (I used black)

- A disc golf disc

To start off with, I am going to need a design. I’m going to use this phoenix-ish design. Also, I’m going to need some adhesive vinyl and an X-acto knife.

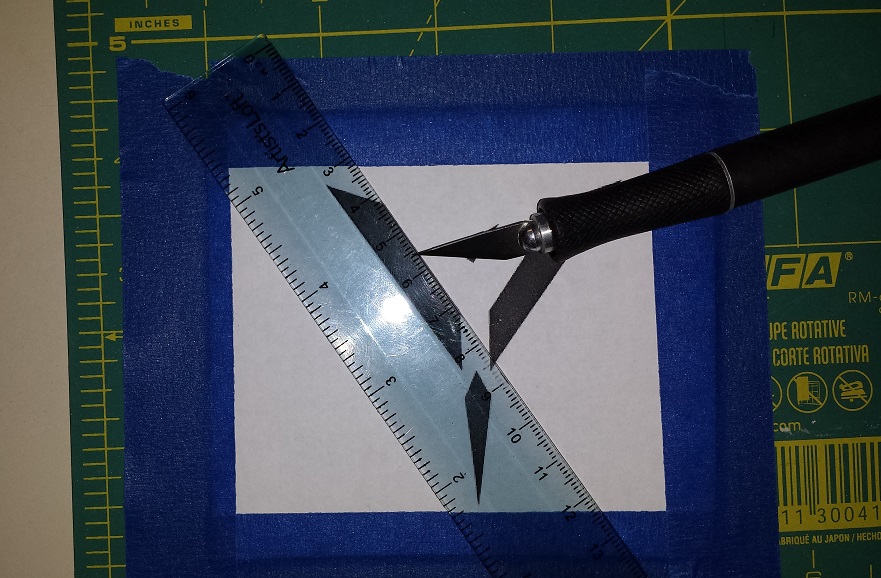

Once the materials are gathered, the first step is to tape down the design on top of the adhesive vinyl. I taped them onto an Olfa cutting mat with blue painters tape. I really like the blue tape because it comes off easy when I’m ready to take it off.

Now, I’m ready to start cutting out the design with the X-acto knife. When I am cutting straight lines, I like to use a ruler because I can’t cut a straight line worth a crap. As I finish cutting out sections of the design, I like to remove them from the work as I go so they don’t get in the way as I go.

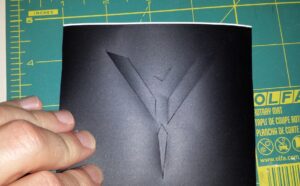

After the entire pattern is cut out, I remove the tape. Be careful when you do this so that you don’t separate the adhesive vinyl from the backing. I like to remove the tape one piece at a time, just to be on the safe side. I’ve gotten into a rush before and tried taking off the whole tape square and the vinyl did pull away from the backing. So, my warnings are based on experience. Once the tape and the pattern have been removed, start removing the cutout sections from the vinyl. As you can see here, I actually cut all the way through the vinyl. That’s ok. If you don’t cut all the way through, just carefully peel the vinyl cutout off of the backing.

At this point, I am ready to start laying out the design on my disc. For better visibility, I cut off some excess vinyl.

Oh, before I forget, before you go any further, wash your disc! If it is a new disc it may have some residual manufacturing oils on it. If it’s an older disc, it may have chemicals or dirt. Either way, whatever gunk is on your disc will cause the dye not to set as well and may also cause the vinyl not to adhere properly.

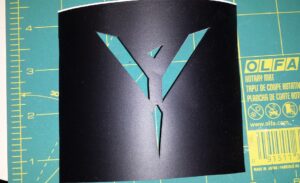

Now, carefully peel the vinyl away from the backing. And even more carefully, place the vinyl on the disc where you want the stencil. Once it is on there, you stand very little chance of getting it off in one piece, especially if it is a more intricate design. So, as a rule of thumb, once it’s on, it’s on. If you don’t like the placement, you will probably have to start over.

dabblesmithUse a straight edge, credit card, gift card, or something similar to smooth out the vinyl. This helps to eliminate any air bubbles in the vinyl and also helps make sure that you have a good seal on your stencil edges. If the edges aren’t sealed, you will end up with dye that has bled out under the edges of the vinyl. And once the dye has set, it’s on there!

So, now I’m ready to prepare the dye. I have some left-over black dye from a previous project and I stored it in an empty drink bottle. Find a microwave safe container, preferably ceramic or glass, and pour enough dye for the project into it. I usually pour an ounce or two. Whatever is left over can always be poured back in with the left-over dye.

Cover the container with a paper towel to prevent splash out, and microwave for 30-40 seconds. This should be enough to warm up the dye enough. Now, I’m no expert, but this is how I have been doing stencil dyeing. I’m sure I read it on the internet somewhere. And I have not tried doing it with straight-up, cold dye. I would be interested to see what the results are and may, someday, try it myself.

Finally ready to apply the dye! As a precaution, place something under the disc and the container with the dye. I’m using a disposable aluminum pan, but newspaper or cardboard work just as well. The applicator I am using is for dyeing leather. I had some of these on hand, but you could probably use cotton swabs, cotton pads, a rag or something similar to apply the dye. I’ve even seen syringes used. Surface tension keeps the dye from running off and keeps most of it inside of the cutout areas.

Now wait… About 20 minutes should do.

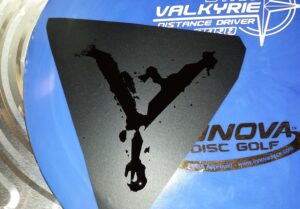

After the dye has has some time to do its thing, rinse the dye off under running cold water. Dry it off with a paper towel and go ahead and remove the vinyl. The vinyl I use I got at Michael’s in the die cutting section. It doesn’t leave any residue and doesn’t come off in too many pieces, either. If any residue is left, it can be removed with regular rubbing alcohol.

That’s it! This process can be used with almost any stencil design and isn’t limited to just disc golf discs.

Kevin